Case Study

IIoT Factory Maintenance Predictive AnalyticsCASE STUDIES

IIoT Factory Maintenance Predictive Analytics

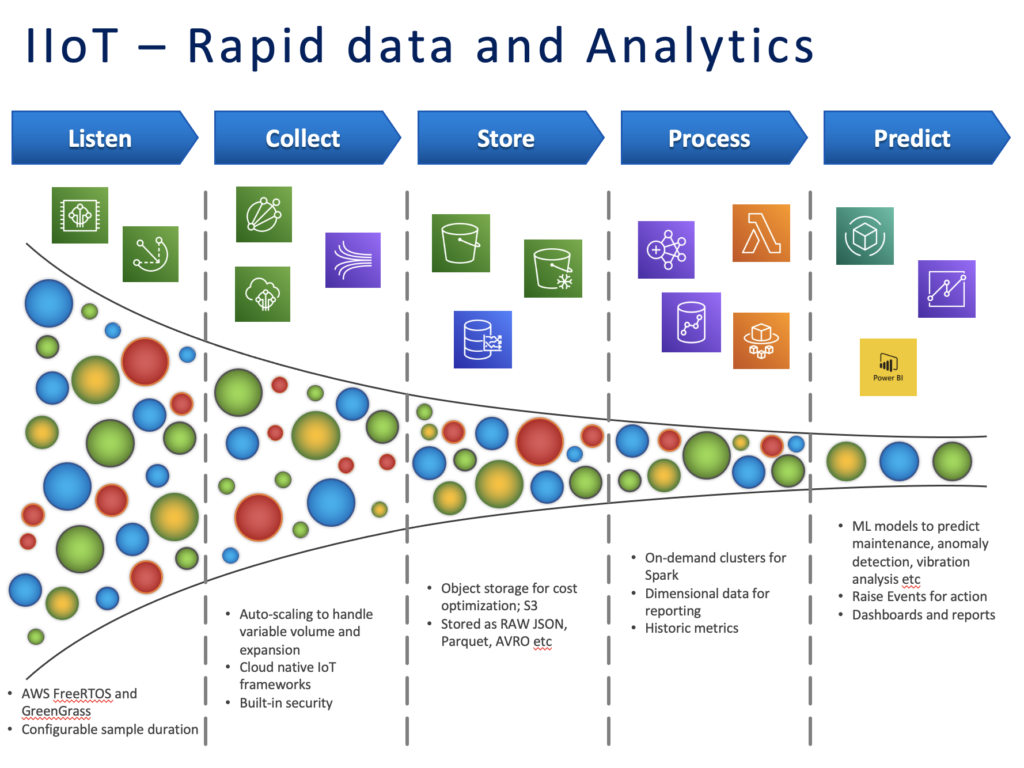

If we can listen to machines and understand their language, we should be able to take better care of them and avoid/reduce downtime. With the advances in Industrial Internet of Things (IIoT) technology we now can listen to machines. By applying Machine Learning algorithms, we can interpret and predict issues and take pro-active action. A native cloud implementation of IIoT will deliver quick results.

We at Qualigy Tech delivered an IIoT solution for a metal manufacturing facility to integrate with sensors on the factory floor to collect and analyze terabytes of telemetry data to predict maintenance needs. Our solution delivered a 40% reduction in downtime for the customer.

IIOT

Details of our Implementation:

Cloud-native implementation on AWS

- End to end solution built using AWS services

- Built-in security and scalability

- Power of ecosystem leading to easier integration between layers

1000+ sensors on the factory floor

- AWS Greengrass for custom sensors

- Integration with existing sensors

- Configurable collection; dial-up/dial-down sampling rate

- Aggregation on the floor to save bandwidth and transfer cost

~10,000TPS

- Multiple channels of collection

- IoT core, Kinesis, FTP, API’s

~150TB per month

- Tiered S3 storage to save cost

- Processed data stored in Avro, Parquet format to enable analytics

Merge fast data (telemetry) with slow data (sales, inventory, etc) for analytics

- Spark engines for processing

- Dimensional data stored on S3 for batch mode and RedShift for reporting

- Modeling using Machine Learning sandbox (Kubernetes containers with ML tools)